The "savoir-faire" of COURBET

Although COURBET have taken the disruptive decision to work only with lab-grown diamonds, the craftsmanship and the know-how in the making of the jewellery are rooted in centuries of tradition. The craftsmen and women in our manufactures bring precious materials to life, revealing the diamond in all its splendour.

It all starts with an idea...

It all starts with an idea, an inspiration, which our artistic director, Marie-Ann Wachtmeister, transcribes into sketches. With the help of her creative team, she develops models that she declines in necklace, ring, earrings...

For a bespoke piece, the design is presented, actual-size, as a gouache that shows the piece from every angle. An artwork in its own right, this rendering enables the head jeweller to understand how the piece will fit together, prepare an assortment of stones, and plan the different stages of production.

The gouache rendering is the basis for the prototype, in wax. Because wax is pliable, the model can be adjusted as many times as necessary to determine its ideal proportions and ensure the piece will be comfortable when worn.

The model is then passed to the caster who attaches it to a sprue (a wax stem) which is fixed to a cast tree, along with other wax models. The tree is set in a flask that is filled with plaster and placed in a kiln. The heat melts the wax which leaves an imprint in the plaster.

For the next stage, molten gold is poured into the void left by the wax

Once the precious metal is cold, the caster breaks the mould, removes the castings from the tree, and discovers what will become the jewellery piece.

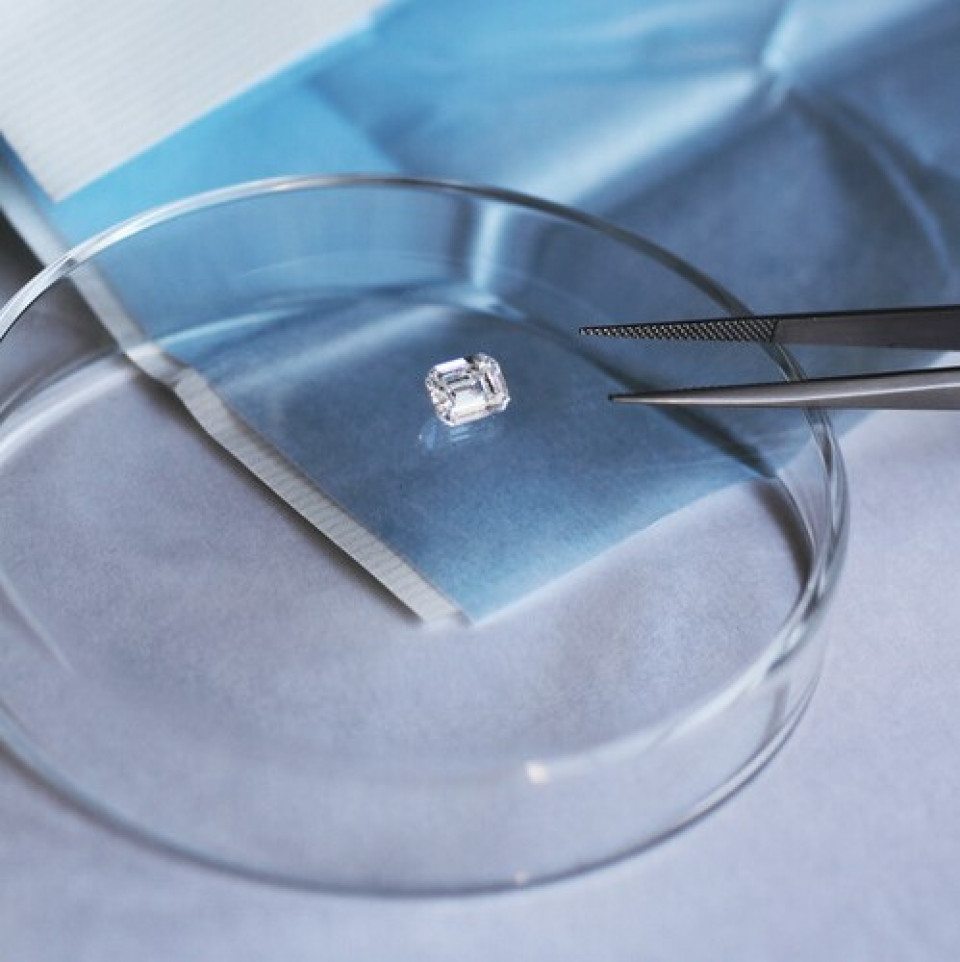

This essential step requires experience, care and no small amount of patience. The mount, for example a ring shank, is now ready to be set with gems. The jeweller checks again the selected stones.

The 4Cs of Cut, Colour, Clarity and Carat, as well as an experienced eye, tell the jeweller when each tiny diamond in a pavé, for example, is a perfect match for the stones on either side.

The piece is then passed to the gem-setter, who secures the stones in the mount. There are many different setting techniques, such as grain, bezel, prong and channel.

Last of all, the polisher removes any trace of the previous stages for a perfect finish.